Sell concrete homes without pouring concrete

There is no doubt today that onsite construction is an obsolete and complex means of building. From cost to delays and unexpected circumstances, the old ways have shown our need for a better, more efficient alternative. Now imagine if your entire home structure, even the foundation, could arrive by truck to your lot in a fully assembled manner. No need to lose time in home wood framing, foundation pouring, roofing or installing windows and exterior doors. No more rain or weather excuses for delays. The perfect team up between on-site and off-site construction, Home Builder and Precast constructors.

Precasters job + Home builders job = Great home!

More and more today, we see a tendency in the market for factory made homes. For a method that better responds to the market ginormous demand, product of the housing crisis in the US where there is more than a 6.8 million homes shortage. Time is of the essence here, and production just can’t keep up with it! The merger between factory and onsite construction presents itself as the next logical step in the industry.

So, how much can we achieve in a factory? These days, we see lots for frame providers. and even though they do help shorten construction times, the process is still tedious and involves too many subareas. How can we rethink this? What innovations are possible? What about a fully finished home exterior? A shell that only needs placement within the lot and that requires you to work only inside the home. This means independence from the weather and a shorter construction time.

Assembly of finished products. That is the new objective in the construction industry. For both customer satisfaction and company gain. Off-site wood or steel structure buildings are a very limited option. Bending and distortions are always gonna be present in such methods. However, the new hot market of concrete building opens a wide new spectrum of possibilities. Such as a new relation between home builders and Precasters.

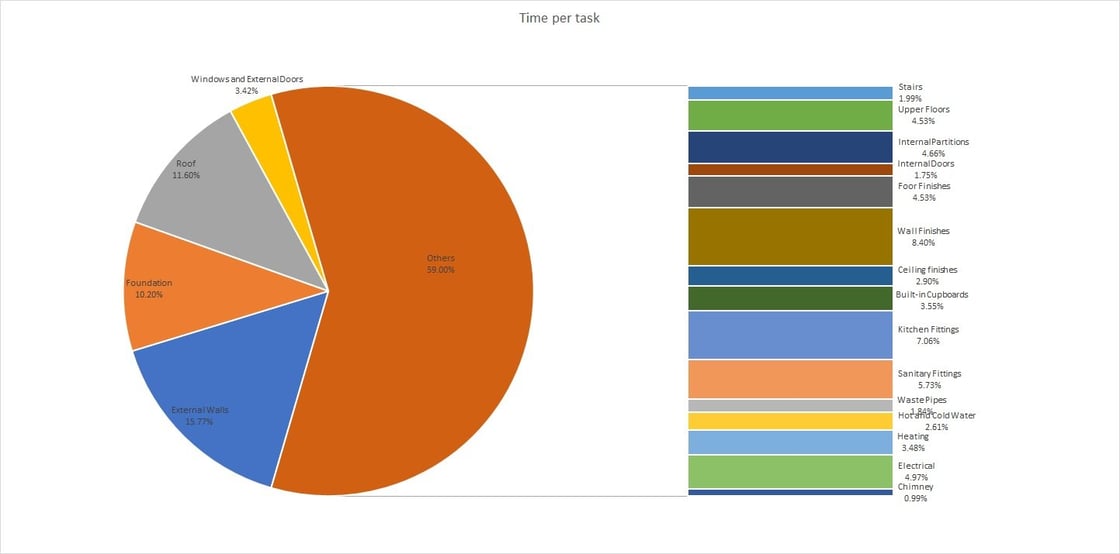

Structure schedule

Day 1 / Day 2

Moreover, a home builder requires a modular, simple and durable shell that can withstand the elements and that allows for a simple inner assembly. All of these without having to invest thousands in new equipment, training and crew. Here is where the new relation takes place. Precasters are not only already able to produce in the required volumes, but also capable of delivering a product that needs no onsite jobs nor a foundation, all of this for a fraction of the price. A completely monolithic and independent structure capable of hosting not only a house but a business, a local market and so much more.

This new approach to construction means a cut in production time by half, a reduction in cost and a jump start in productivity. The possibilities for improvement are limitless, and the introduction to 2.0 to 4.0 industry is an objective our sector desperately needs. Thanks for reading this far and for this and more info on the pain points of construction please register below.

Register

Construcción Modular